Italian manufacturers

since 1976

For more than 40 years of business, Armani Carrelli Elevatori has become a reference leader in the forklift industry, which are particularly suitable in situations characterized by reduced spaces and in logistical situations that require the greatest versatility.

Armani: Versatile solutions for

cargo manipulation in industry

Armani’s product range enables the satisfaction of the most diverse needs within the goods handling industry in warehouses, plants and production departments. From conventional forklifts and pallet trucks for handling palletized goods, the offered products are complemented by specific solutions for hauling and handling goods, for handling rolls, drums and industrial containers, up to machines specially developed for handling loads of exceptional dimensions and weight.

Stackers

Speedy Light Evo

105/16

Speedy Plus Evo

120/16

Master Light

2,900 - 3,300 kg

Master Plus

2,500 - 3,500 kg

Delta AC

1,600 - 3,500 kg

Pallet trucks

Smart Light/

Plus Evo

Discovery

Compact AC Evo

Discovery

2,000-4,000 kg

Challenger AC Evo

1,500-2,000 kg

TPE HL AC-evo

TPM 20

Towing and transport

TPT AC Evo

40/50/60

TPT HL AC/UB-evo

TPP AC Evo

20/40/60

TPP HL AC-evo

Forklifts

Speedy Light Evo

105/16 INOX

Master Light/Plus

Evo 105/29/

120/25/30 INOX

Delta E AC-evo

125/16/25/30/35 INOX

Delta E AC-evo

145/16/25/30 INOX

Delta CP AC Evo

100/16 STAINLESS STEEL

Lifting tables

Electric pantograph tables for lifting

Manual pantograph tables for lifting

Work tables for lifting

Tilting tables for lifting

Stackers with rolls and reels

Clamps

Shaft clamps

Manipulators

Molded forks

Spikes

Bearings

Drum handling

Barrel tilt ring

Barrel tilting clamps

Handling of industrial containers

Container tipping equipment

Container tilting equipment

Clamps for containers

Speedy Light evo 105/16

up to 1,000 kg

Maneuvering and Safety:

Thanks to the innovative DR EVO drive system, the operator can use the maximum controllability, maneuverability and safety provided by the new control lever completely designed by the ARMANNI R&D team, which integrates the new “turtle” function and the two-speed ascent/descent control system.

Master Light 2,900 – 3,300 kg

The simplex mast of the Master Light evo 105/29 model enables the lifting of loads of up to 1000 kg to a maximum height of 2900 mm.

Maneuvering and Safety:

Thanks to the innovative DR EVO drive system, the operator can have maximum controllability, maneuverability and safety ensured by the new steering arm completely designed by the ARMANNI research and development team, which integrates the new “turtle” function and the two-speed bidirectional movement control system.

Smart Light/Plus – here it is

Smart Light – evo 150/200 enables the handling of goods from 1500 to 2000 kg.

Compact as a hand palette:

Maximum compactness (1150mm) is already provided in the standard version, and it can be further increased by choosing equipment with shortened forks of 800 or 1000 mm (no extra charge) for movement in spaces characterized by insufficient space such as trucks or containers.

Discovery Compact AC is here

Discovery Compact AC-evo enables the handling of goods up to 2000 kg.

Compactness

Optimized dimensions that ensure maximum compactness, even with a 160 Ah battery, facilitate work even in tight spaces.

Discovery 2,000-4,000 kg

Discovery AC evo enables the handling of goods from 2000 to 4000 kg.

Compactness

Optimized dimensions that ensure maximum compactness, even with a 160 Ah battery, facilitate work even in tight spaces.

Challenger AC is 1,500-2,000 kg

Discovery AC evo enables the handling of goods from 2000 to 4000 kg.

Compactness

Optimized dimensions that ensure maximum compactness, even with a 160 Ah battery, facilitate work even in tight spaces.

TPE HL AC-evo

TPE HL AV – evo is compatible with 24V or 48V motors and enables lifting loads of up to 20,000 kg.

Compactness

The frame and components of the traction system (with 24V or 48V) and the lifting system, specifically designed for the most difficult working conditions, enable the safe handling of exceptional loads.

TPM 20

The TPM 20 enables the handling of loads up to 2000 kg.

Strength and reliability

Simple but solid structures characterized by quality components and a high degree of resistance, all to ensure maximum efficiency; the highly resistant structure and levers have a positive effect on the life of the machine, ensuring maximum efficiency over the years, even when used regularly and intensively.

TPT AC-evo 40/50/60

TPT AC-evo enables towing loads up to 6000 kg and lifting loads (via the suspension system) up to 2000 kg.

Maximum autonomy

The standard armored traction battery ensures full autonomy of use.

TPT HL AC/UB-evo

TPT HL AC/UB – evo, with 24V or 48V motors, enables towing loads up to 25,000 kg.

Maximum autonomy

The standard armored traction battery ensures full autonomy of use.

TPP AC-evo 20/40

TPP AC-evo 20 enables handling loads up to 2000 and 40000 kg.

Maximum autonomy

The standard armored traction battery ensures full autonomy of use.

TPP HL AC-evo

TPP AC-evo 20 enables handling loads up to 2000 and 40000 kg.

Components

The frame and components of the traction system (with 24 or 48V) and lifting equipment are specially designed for the toughest working conditions and enable safe handling of even exceptional loads.

Speedy Light evo 105/16 INOX

Management and security:

Thanks to the innovative DR EVO drive system, the operator can enjoy maximum controllability, maneuverability and safety provided by the new control lever completely designed by ARMANNI’s R&D team, which integrates the new “turtle” function and the bidirectional lift/lower control system.

Master Light evo 105/29 INOX

Light and ergonomic, but at the same time strong and reliable, Master Light INOX and Master Plus INOX represent the most successful compromise between the requirements for strength and agility in minimal space.

Maneuvering and Safety:

Thanks to the innovative DR EVO control system, the operator can enjoy maximum controllability, maneuverability and safety provided by the new control arm, completely designed by the ARMANNI R&D team, which integrates a new “turtle” function and a two-speed lifting/lowering speed control system .

Delta E AC-evo 145/16/25/30 INOX

DELTA E AC-evo INOX, completely made of stainless steel, represents the most concrete answer to the requirements for strength, ergonomics and safety in the movement sector, being the ideal solution for intensive work involving the movement of goods on pallets in medium/large environments.

DELTA E INOX is the version with extruded grease; thanks to its special steel profiles, it is possible to achieve even better performance, especially with special and very heavy loads.

Strength and reliability

Thanks to the strength of the construction, it is possible to move in completely safe conditions, transporting significant loads with outstanding residual capacities at significant heights, while at the same time ensuring reduced dimensions and good visibility from the driver’s position.

Delta CP AC-evo 100/16 INOX

The stainless steel frame and components make the forklift particularly suitable for working in environments subject to oxidation phenomena due to the presence of moisture, condensation, dust and salt solutions. The simplex mast model DELTA CP AC-evo 100/16 INOX enables the lifting of loads up to 1000 kg to a maximum height of 1600 mm.

FEM fork holder and forged cantilever forks

Equipment with adjustable forged forks allows the forklift to lift pallets and/or containers of non-standard dimensions even from the “closed” side. Standard equipment with a FEM fork holder allows easy application of clamps and hydraulic equipment, providing the forklift with additional hydraulic capabilities.

Shaft clamps

Collection/Deposit/Storage

Handling solutions equipped with clamps for expandable pneumatic shafts enable all operations of retrieval, depositing and storage from the machine to the storage station to be carried out in complete safety and with exceptional ease. Thanks to this practical solution, it is possible to perform the operation in a few seconds, without the need for fixed cranes or overhead crane systems. Thanks to optional accessories such as a beam laser pointer, a high-definition camera and a side-shift accessory, absolute precision in the retrieval phase is guaranteed.

Manipulators

Rotation/Withdrawal/Deposit

By means of a specific expandable mandrel, the manipulators allow the roll to be taken from its core. In this way, the operator can carry out pick-up, rotation and deposit operations in an extremely simple and safe way, using one machine to handle rolls of different materials and sizes.

Shaped forks

Handling/Storage

Conventional lifting forks are appropriately sized and shaped to the length and diameter of the roll being handled to ensure perfect interaction with the load surface. They can be installed on pallet trucks for floor-level handling or on forklifts for above-floor storage operations.

Specifications

Spikes

Pickup/Deposit/Storage

Using a tool with a single cylindrical fork (spike) of the appropriate length and diameter, you can lift and handle the rolls through their core. The spike can be installed on any standard forklift and allows the operator to handle the load at different lift heights.

Specifications

Bearings

Withdrawal/Deposit

Specially shaped according to the characteristics of the rolls, the cradle-shaped equipment is an ideal tool for safely positioning the roll during manipulative operations. They can be equipped with a suitable hydraulic mechanism and allow simple release/deposit of the rolls without the need for manual pushing by the operator.

Specifications

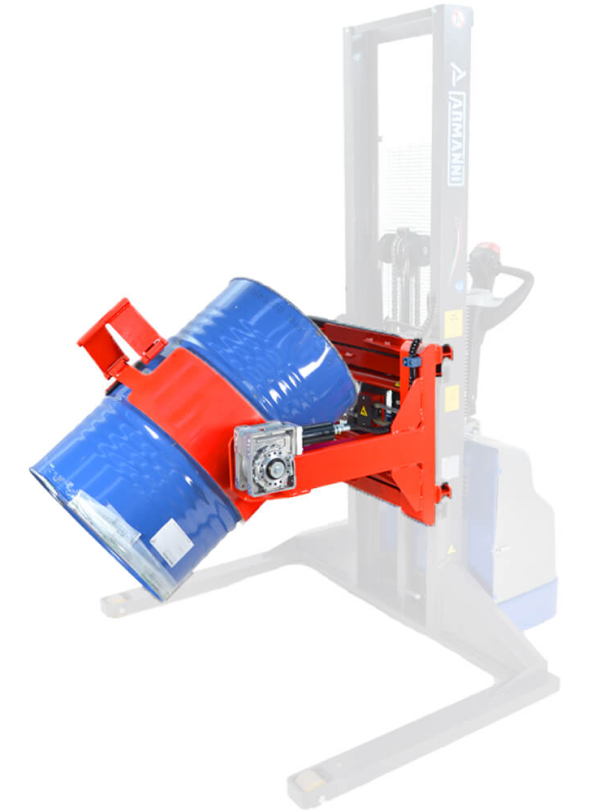

Barrel tilt ring

Emptying the barrel

A ring-shaped system surrounds the load over the outer diameter and allows a firm hold of the keg, with a gradual controlled discharge of the contents forward or sideways. The mechanical or electro-hydraulic rotation mechanism can be manually or automatically operated.

Specifications

Barrel tilting clamps

Unloading/Handling of barrels

Clamps used for handling and emptying kegs allow containers of various diameters to be safely gripped by opening and closing appropriately shaped holding arms. Electro-hydraulic mechanism for frontal or lateral rotation enables gradual and controlled emptying of the barrel.

Specifications

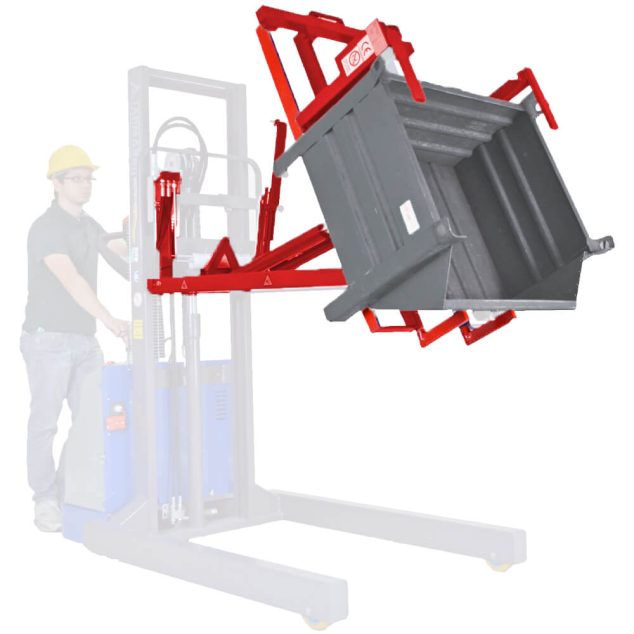

Container tipping equipment

Front/side discharge

By means of specific manual or hydraulic clamping mechanisms, frontal or side tipping machines enable the load to be firmly gripped so that it can later be tipped to the desired height. The drive with electrohydraulic servovalves allows gradual and controlled emptying of the contents, ensuring greater efficiency and safety when handling this type of cargo.

Specifications

Container tilting equipment

Leaning forward/sideways

Hydraulic devices that are adequately incorporated into the lifting system of the forklift to enable frontal or lateral tilting of the lifted load. The ability to tilt the container in a gradual and controlled manner effectively supports the operator in terms of ergonomics and efficiency during the operations of retrieving contents from containers of different shapes and sizes.

Specifications

Clamps for containers

Pickup/Movement/Deposit/Handling

Devices equipped with clamps allow a firm grip on the side of the container to safely lift, handle and place it in the desired location. These devices can be equipped with devices for frontal or lateral turning, enabling the performance of tilting and emptying operations. Thanks to the full adaptability of the holding arms, you fit perfectly into containers (of different shapes, sizes and materials) with equipment to perform all operations of handling this type of cargo in an efficient and safe way.

Specifications

Work tables for lifting

Lifting tables on castors with vertical lifting by means of a piston, which can be operated electro-hydraulic or manually; the control handle allows manual movement of the lifting table, so it can serve workstations located in different positions.

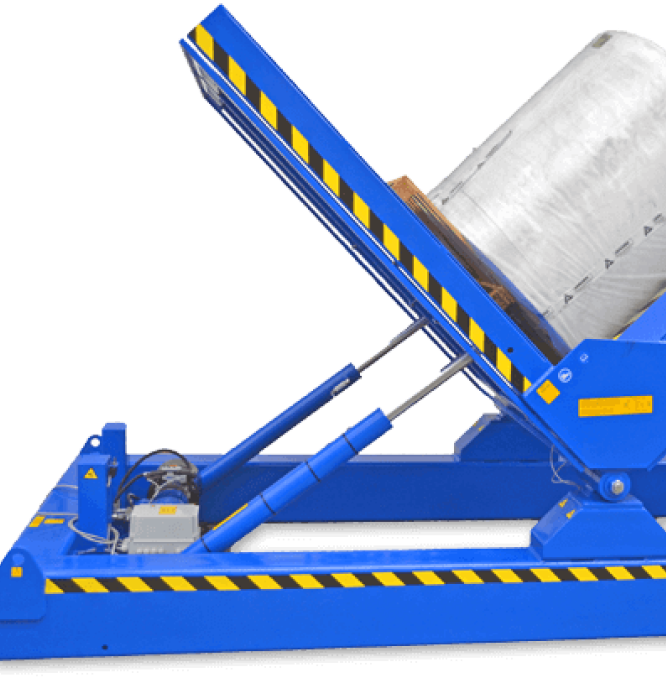

Tilting lifting tables

Systems equipped with an L-shaped platform that tilts electro-hydraulically until the load is completely overturned. The size and shape of the lifting tables can be adjusted to perfectly match the type and shape of the goods being processed.

Manual pantograph tables for

lifting

Lifting tables on castors with pantographic lifting manually operated by means of a lifting pump; the control handle allows manual movement of the lifting table, so it can serve workstations located in different positions. The products offered by Armani allow you to choose between several standard settings (capacity, platform size and lifting stroke) or, if necessary, request an adjustment of the dimensions according to the specific needs of the workplace. Ability to equip lifting platforms with a vertical double pantographic lifting system to achieve maximum heights with minimum overall dimensions. A wide range of additional options, such as rolls, tilting or rotating loading platforms and many others, to adapt the lift table to specific intended uses.

Electric pantograph tables for

lifting

A comprehensive range of lifting tables with electro-hydraulic lifting by means of a pantograph mechanism; the products offered by Armani allow you to choose between several standard settings (capacity, platform size and lifting stroke) or, if necessary, request an adjustment of the dimensions according to the specific needs of the workplace.

Delta AC 1,600 – 3,500kg

The simplex mast Delta AC evo 125/16 enables the lifting of loads up to 1200 kg to a maximum height of 1600 mm.

Robustness and reliability

Thanks to the strength of the structure, it is possible to move in completely safe conditions, transporting significant loads with excellent remaining capacities at noticeable heights, while at the same time ensuring reduced dimensions and good visibility from the driver’s position.

Master Plus 2,500 – 3,500 kg

The simplex mast of the Master Plus evo 120/25 model enables the lifting of loads of up to 1200 kg to a maximum height of 2500 mm.

Maneuvering and Safety:

Thanks to the innovative DR EVO drive system, the operator can use the maximum mobility, maneuverability and safety provided by the new steering arm completely designed by the ARMANNI R&D team, which integrates the new “turtle” function and a two-speed ascent/descent control system .

Speedy Light evo 120/16

The single-stage mast of the Speedy Plus evo 120/16 model allows lifting loads of up to 1200 kg to a maximum height of 1600 mm.

Maneuvering and Safety:

Thanks to the innovative DR EVO steering system, the operator can enjoy maximum controllability, maneuverability and safety, guaranteed by the new steering handle completely designed by the ARMANNI R&D team, which integrates the new “turtle” function and the ascent/descent control system with two speeds.

Minimal space occupancy

Thanks to design studies and single-stage grease, the dimensions of the Speedy Light evo 105/16 model have been reduced to a minimum, allowing the user to operate comfortably even in narrow warehouses and in difficult conditions.

Minimal space occupancy

Thanks to design studies and single-stage grease, the dimensions of the Speedy Light evo 105/16 model have been reduced to a minimum, allowing the user to operate comfortably even in narrow warehouses and in difficult conditions.

Stability on any surface

The structure with 5 contact points, with a specific cushioning system, ensures perfect adhesion between the drive wheel and the floor, even when there are irregularities or extreme unevenness.

Great autonomy

The use of 24V traction batteries with a capacity of up to 270Ah provides a great autonomy of the stacker, thanks to which it is possible to use it intensively for many consecutive hours. With the integrated battery charger, it is possible to charge the battery by connecting directly to a 220V power supply.

Maximum efficiency

The braking phase involves the activation of a specific energy recovery system which, together with the search for the lowest levels of consumption, ensures more work cycles each time the battery is charged.

Maximum autonomy

The standard armored traction battery ensures full autonomy of use.

Maximum autonomy

The standard armored traction battery ensures full autonomy of use.

Maximum autonomy

The standard armored traction battery ensures full autonomy of use.

Maneuvering and Safety:

The drive with power assistance is standard equipment and allows the operator to steer without any physical effort and with maximum precision.

Maneuvering and Safety:

The ergonomic handle facilitates maneuvering and ensures safe and comfortable work; lift-lower-measure operations are facilitated by a three-position lever lift pump, which ensures complete control through the operator’s hand.

Minimal efficiency

The braking phase involves the activation of a specific energy regeneration system which, together with the tendency towards the lowest levels of consumption, ensures more work cycles each time the battery is charged.

Minimal efficiency

The braking phase involves the activation of a specific energy regeneration system which, together with the tendency towards the lowest levels of consumption, ensures more work cycles each time the battery is charged.

Easy maneuverability in safe conditions

Standard equipment with servo-assisted guidance allows the operator to maneuver without any physical effort and with maximum precision.

Minimum amount of space

Thanks to design studies and a single-stage stand, the dimensions of the Speedy Light evo 105/16 forklift have been reduced to a minimum of space, allowing the user to operate comfortably even in narrow warehouses and difficult environments.

Maximum autonomy

The use of 24V traction batteries with a capacity of up to 270Ah provides a high autonomy to the forklift, enabling intensive use for many consecutive hours. With the integrated battery charger, it is possible to recharge the battery by connecting directly to the 220V power line.

Lifting/storage of loads under difficult conditions

The lack of support legs on the ground allows the load to be approached to the fork shoulder without the negative impact of the lower frame of the forklift on the load base, thus allowing comprehensive access even in the presence of obstacles on the ground.

Special steel profile

The choice of special steel grease profiles ensures outstanding performance both for forklifts intended for intensive handling of heavy loads, and for forklifts equipped with specific hydraulic equipment for handling special loads.

Stability, slope and residual capacities

The counterweight structure ensures maximum stability thanks to the standard swivel column that holds the load in the correct position; the specific construction of the frame and the special distribution of the counterweight system help to ensure good residual capacities.

Maneuvering and Safety:

Thanks to the innovative DR EVO control system, the operator can enjoy maximum controllability, maneuverability and safety provided by the new control arm, completely designed by the ARMANNI R&D team, which integrates a new “turtle” function and a two-speed lifting/lowering speed control system .

Power steering and AC technology

Equipment with a steering servo-mechanism allows the operator to maneuver safely and effortlessly even under full load; AC drive technology ensures maximum responsiveness, very good start, good performance on slopes and high braking safety.

Maximum autonomy

The structure with 5 contact points, supported by a specific shock absorber system, ensures perfect adhesion between the drive wheel and the floor, even when there are irregularities or extreme unevenness.

Minimal efficiency

The braking phase involves the activation of a specific energy regeneration system which, together with the tendency towards the lowest levels of consumption, ensures more work cycles each time the battery is charged.

Maximum efficiency

The braking phase involves the activation of a specific energy recovery system which, together with searching for the lowest consumption levels, ensures more work cycles each time the battery is charged.

Maximum efficiency

The braking phase involves the activation of a specific energy recovery system which, together with searching for the lowest consumption levels, ensures more work cycles each time the battery is charged.

Maximum control

The strong and powerful traction system is combined with fork lift systems or platform lift systems that can be adjusted to best suit the load being lifted. Studying the perfect interface between the fork and the load allows for maximum stability during handling.

Price and quality ratio

Thanks to components derived from research and many years of experience, it is possible to ensure a product of guaranteed quality at a very reasonable price.

Maximum control

Thanks to the advanced system used in the traction system, it is possible to precisely adjust the speed, as well as ensure complete safety during loading and unloading operations, even on ramps, through the ANTI ROLL-BACK system, which allows moving uphill without going back, and ANTI ROLL -DOWN system, thanks to which the machine is always under torque control, even downhill.

Maximum control

Thanks to the advanced system used in the traction system, it is possible to precisely adjust the speed, as well as ensure complete safety during loading and unloading operations, even on ramps, through the ANTI ROLL-BACK system, which allows moving uphill without going back, and ANTI ROLL -DOWN system, thanks to which the machine is always under torque control, even downhill.

Maximum control

Thanks to the advanced system used in the traction system, it is possible to precisely adjust the speed, as well as ensure complete safety during loading and unloading operations, even on ramps, through the ANTI ROLL-BACK system, which allows moving uphill without going back, and ANTI ROLL -DOWN system, thanks to which the machine is always under torque control, even downhill.

Maximum autonomy

The standard armored traction battery ensures full autonomy of use.

Stability on any surface

The structure with 5 points of contact with a specific cushioning system ensures perfect adhesion between the drive wheel and the floor, even when there is unevenness or extreme unevenness.

Maximum autonomy

The standard armored traction battery ensures full autonomy of use.

Maximum control

Thanks to the advanced system used in the traction system, it is possible to set the speed with maximum precision, as well as ensure complete safety in loading and unloading operations, even on ramps, with ANTI ROLL-BACK, i.e. starting uphill without moving backwards, and ANTI ROLL -DOWN, thanks to which the machine is always under torque control, even downhill.

Maximum control

Thanks to the advanced system used in the traction system, it is possible to set the speed with maximum precision, as well as ensure complete safety in loading and unloading operations, even on ramps, with ANTI ROLL-BACK, i.e. starting uphill without moving backwards, and ANTI ROLL -DOWN, thanks to which the machine is always under torque control, even downhill.

Maximum control

Thanks to the advanced system used in the traction system, it is possible to set the speed with maximum precision, as well as ensure complete safety in loading and unloading operations, even on ramps, with ANTI ROLL-BACK, i.e. starting uphill without moving backwards, and ANTI ROLL -DOWN, thanks to which the machine is always under torque control, even downhill.

Maximum control

Thanks to the advanced system used in the traction system, it is possible to set the speed with maximum precision, as well as ensure complete safety in loading and unloading operations, even on ramps, with ANTI ROLL-BACK, i.e. starting uphill without moving backwards, and ANTI ROLL -DOWN, thanks to which the machine is always under torque control, even downhill.

Maneuvering and Safety:

Thanks to the innovative DR EVO driving system, the operator can enjoy maximum controllability, maneuverability and safety, ensured by the new steering arm completely designed by the ARMANNI R&D team, which integrates the new “turtle” function and the raising/lowering control system with two speed levels.

Maneuvering and Safety:

Thanks to the innovative DR EVO drive system, the operator can benefit from maximum controllability, maneuverability and safety provided by the new steering arm designed entirely by the ARMANNI R&D team, which integrates a new turtle function and a two-speed ascent / descent control system.

Maneuvering and Safety:

Thanks to the innovative DR EVO drive system, the operator can benefit from maximum controllability, maneuverability and safety provided by the new steering arm designed entirely by the ARMANNI R&D team, which integrates a new turtle function and a two-speed ascent / descent control system.

Maneuvering and Safety:

Thanks to the innovative DR EVO drive system, the operator can benefit from maximum controllability, maneuverability and safety provided by the new steering arm designed entirely by the ARMANNI R&D team, which integrates a new turtle function and a two-speed ascent / descent control system.

Maneuvering and Safety:

Thanks to the innovative DR EVO drive system, the operator can benefit from maximum controllability, maneuverability and safety provided by the new steering arm designed entirely by the ARMANNI R&D team, which integrates a new turtle function and a two-speed ascent / descent control system.

Maximum efficiency

The braking phase involves the activation of a specific energy regeneration system which, together with the tendency towards the lowest levels of consumption, ensures more work cycles each time the battery is charged.

Adaptability

Possibility of maximum adaptability, in terms of fork length and outer width, as well as wheel material (rubber, vulcolan, nylon) according to the specifications of the working surface to ensure the best smoothness. It is also possible to adjust the type of roller at the end of the fork; it is available in single or double version.

Maneuvering and Safety:

Thanks to the innovative DR EVO control system, the operator can enjoy maximum controllability, maneuverability and safety provided by the new control arm, completely designed by the ARMANNI R&D team, which integrates a new “turtle” function and a two-speed lifting/lowering speed control system .

Maneuvering and Safety:

Thanks to the innovative DR EVO control system, the operator can enjoy maximum controllability, maneuverability and safety provided by the new control arm, completely designed by the ARMANNI R&D team, which integrates a new “turtle” function and a two-speed lifting/lowering speed control system .

Maneuvering and Safety:

Thanks to the innovative DR EVO control system, the operator can enjoy maximum controllability, maneuverability and safety provided by the new control arm, completely designed by the ARMANNI R&D team, which integrates a new “turtle” function and a two-speed lifting/lowering speed control system .

Maximum efficiency

The braking phase involves the activation of a specific energy regeneration system which, together with the tendency towards the lowest levels of consumption, ensures more work cycles each time the battery is charged.

Mandatory maintenance

Maintenance operations are facilitated by the simple opening of the body, which allows unobstructed access to the machine, and the ability to instantly identify faults through the check LEDs.

Special steel profile

The choice of special steel grease profiles ensures outstanding performance both for forklifts intended for intensive handling of heavy loads, and for forklifts equipped with specific hydraulic equipment for handling special loads.

Stability on any surface

The structure with 5 contact points, supported by a specific shock absorber system, ensures perfect adhesion between the drive wheel and the floor, even when there are irregularities or extreme unevenness.

Maximum autonomy

Equipment with shielded 24V batteries with capacities up to 270Ah ensures a high degree of autonomy during intensive use; the integrated battery charger enables the battery to be charged by connecting it directly to the 220V mains.

Stability on any surface

The structure with 5 points of contact with a specific cushioning system ensures perfect adhesion between the drive wheel and the floor, even when there are irregularities or extreme unevenness.

Mandatory maintenance

Maintenance of operations is facilitated by a simple opening system of the body, which allows access to the interior of the machine without obstacles, and the ability to immediately identify faults through LED check lights.

Mandatory maintenance

Maintenance operations are facilitated by a simple body opening system, which allows unobstructed access to the machine body, and the ability to immediately identify faults through the LED check.

Stability on any surface

The structure with 5 points of contact, with a specific damping system, ensures perfect adhesion between the drive wheel and the floor, even when there are irregularities or extreme unevenness.

Stability on any surface

The structure with 5 contact points surrounded by a specific shock absorber system (SGS, Super Grip system) ensures perfect adhesion between the drive wheel and the floor, even when there are bumps or extreme robustness.

Stability on any surface

The structure with 5 points of contact with a specific damping system ensures perfect adhesion between the drive wheel and the floor, even when there is a bump or extreme irregularity.

Mandatory maintenance

Maintenance operations are facilitated by simply opening the bodywork, which allows entry into the machine without obstacles, as well as the ability to immediately identify faults through LED controls.

Stability on any surface

The structure with 5 points of contact with a specific damping system ensures perfect adhesion between the drive wheel and the floor, even when there is a bump or extreme irregularity.

Mandatory maintenance

Maintenance operations are facilitated by simply opening the bodywork, which allows entry into the machine without obstacles, as well as the ability to immediately identify faults through LED controls.

Rear-wheel Drive Electric Forklift – FE3R16NC

The FE3R N series is a lightweight three-wheel rear-wheel counterbalanced electric forklift.

This ergonomically designed forklift combines the best aesthetics and technology.

With its compact dimensions and excellent operational flexibility and comfort, easy maintenance and use, and high reliability, the FE3R N series is the ideal choice for a variety of applications.

Specifications

Limited outdoor use

Four-wheel Electric Forklift – FE4P40-50Q

Compared to the N series, the Q series four-wheel electric forklift is significantly more compact and therefore more suitable for working in confined spaces. The Q Series is also designed with moderate applications in mind, offering high levels of comfort and efficiency.

The standard configuration is an 80V/412Ah Lithium Iron Phosphate (LFP) battery with efficient fast charging (fully charged in 2-3 hours). The battery is located at the bottom of the chassis to ensure greater stability thanks to the low center of gravity.

Specifications

Long arm parking brake gear

Maintenance-free AC motor

Four-wheel Electric Forklift – FE4P30-35Q

The FE4P30/35Q is an economical electric forklift that combines the advantages of a traditional internal combustion forklift and a lithium iron battery powered forklift. This heavy-duty forklift offers a spacious and comfortable driving experience.

The yoke system, front and rear axles, and chassis durability are also similar to a traditional internal combustion forklift. This durability, along with the benefits of a lighter electric forklift layout with an optimized center of gravity, improves the forklift’s energy consumption.

Specifications

Suitable for outdoor use

Four-wheel Electric Forklift – FE4P30-35N

The creative, dynamic and elegant design of the FE4P N series provides excellent reliability, easy maintenance and efficient and comfortable operation.

The stylish and robust metal design of the outer covers ensures optimal safety.

This forklift can be equipped with a lead-acid or lithium-ion battery. The battery is located at the bottom of the chassis to ensure greater stability thanks to the low center of gravity.

Specifications

Low energy consumption

High frequency MOSFET integrated controller

Four-wheel Electric Forklift – FE4P25-28Q

The FE4P25/28Q is an economical electric forklift that combines the advantages of a traditional internal combustion forklift and a lithium-iron battery powered forklift. This heavy-duty forklift offers a spacious and comfortable driving experience.

The yoke system, front and rear axles, and chassis durability are also similar to a traditional internal combustion forklift. This durability, along with the benefits of a lighter electric forklift layout with an optimized center of gravity, improves the forklift’s energy consumption.

Specifications

Suitable for outdoor use

Four-wheel Electric Forklift – FE4P16-25N

The creative, dynamic and elegant design of the FE4P N series provides excellent reliability, easy maintenance and efficient and comfortable operation.

The stylish and robust metal design of the outer covers ensures optimal safety.

This forklift can be equipped with a lead-acid or lithium-ion battery. The battery is located at the bottom of the chassis to ensure greater stability thanks to the low center of gravity.

Specifications

Low energy consumption

High frequency MOSFET integrated controller

Four-wheel Electric Forklift – FE4P16-20Q

The design of the Q Series is based on Noblelift’s original E Series and current N Series, combining the strengths of both to offer an efficient and comfortable series for light and medium duty applications.

This forklift can be equipped with a lead-acid or lithium-ion battery, and the battery types are completely interchangeable.

With a lowered center of gravity and overhead protection, the Q Series is ideal for use in confined spaces, such as elevator entry.

Specifications

Three-wheeled Rear Drive Electric Forklift – FE3R12N

Series N – For indoor use

The FE3R N series is a lightweight three-wheel rear-wheel counterbalanced electric forklift.

This ergonomically designed forklift combines the best aesthetics and technology.

With its compact dimensions and excellent operational flexibility and comfort, easy maintenance and use, and high reliability, the FE3R N series is the ideal choice for a variety of applications.

Specifications

Forklift with clamp that rotates frontally by 90° / 360°

Specifications

*both options are available (electro-hydraulic and manual).

Note: Load tilt drive, load lift and forklift drive options are listed here.

Note: Load tilt drive, load lift and forklift drive options are listed here.

Pallet trucks also adapted for the transport of extra heavy and large loads

For internal use

Limited outdoor use